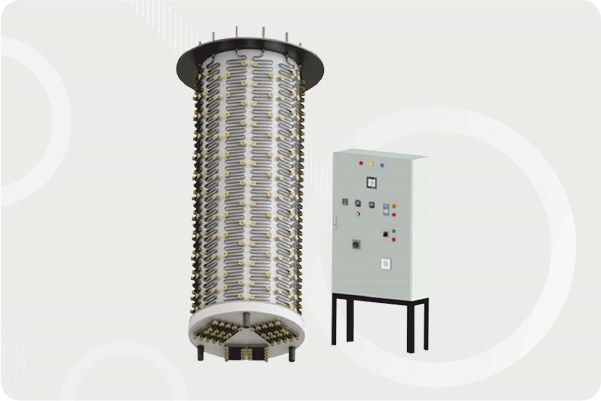

Sintering Heater

The Sintering Heater delivers precise temperature control for efficient thermal processing.

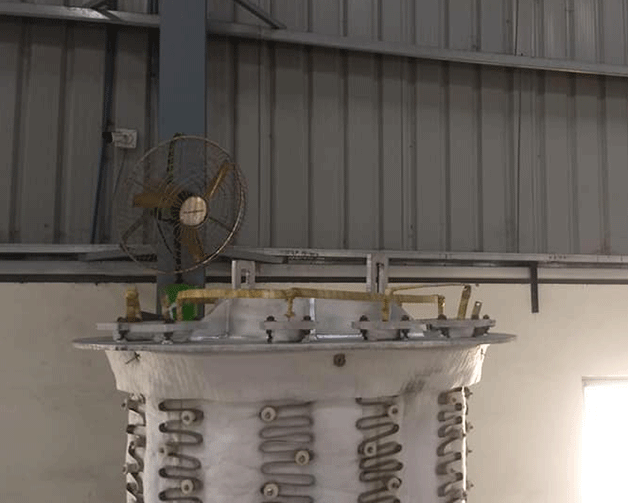

LeisterTech’s Sintering Heater is the latest innovation in the heating of ramming mass, designed to provide superior efficiency and performance. It employs advanced technology to reduce heat and power loss, ensuring that your materials reach a rock-solid state with optimal resource usage. By heating materials to 500°C, it effectively removes moisture content from the ramming lining mixture, leading to better results and increased durability of the crucible.

What is a Sintering Heater?

A Sintering Heater is a specialized heating system used primarily in the Steel Plants and foundries to heat ramming mass, a refractory material used to line the interior of induction furnaces. The sintering process is crucial in removing moisture from the lining mixture and consolidating it into a hard, durable layer. This creates a robust and solid surface, ready to withstand the extreme conditions of metal melting operations.

The LeisterTech Sintering Heater offers precise temperature control for consistent sintering results.

Efficient Heat Transfer

Reduced Power Consumption

Custom Fit Design

Ni-Cr Strip-Based Heating

Ease of Use

Enhanced Crucible Performance

High-precision heater for uniform sintering, enhancing material strength in industrial processes.

| Sr. No. | Model | Furnace |

|---|---|---|

| KW | ||

| 1 | 90 | 6T |

| 2 | 110 | 10T |

| 3 | 150 | 15T |

| 4 | 180 | 20T-25T |

| 5 | 250 | 30T-40T |

High-precision sintering up to 1600°C, customizable chamber, digital PID control, and advanced safety features.

Operating Temperature

Heating Element

Power Supply

Applications

Power Savings

Improved Material Quality

Precision Heating

Custom Solutions

Find quick answers to common questions about Sintering Heater.

What is a sintering heater used for?

A sintering heater is used to heat ramming mass, solidifying it to prepare the crucible for metal melting processes in foundries and metalworking industries.

How does a sintering heater work?

The heater uses Ni-Cr strips housed in custom-designed vessels to reach temperatures of up to 500°C, removing moisture and hardening the ramming lining mixture.

What is ramming mass, and why is sintering important?

Ramming mass is a refractory material used to line induction furnaces. Sintering is essential for consolidating the material into a hard, durable state, ensuring better furnace performance.

What are the benefits of using a sintering heater?

A sintering heater improves efficiency by reducing heat and power loss, minimizes manual effort, and ensures consistent, high-quality results in furnace preparation.

How does the Ni-Cr strip technology enhance performance?

Ni-Cr strips are highly efficient at conducting heat, allowing for uniform heating throughout the vessel and ensuring optimal sintering results.

Is the sintering heater customizable?

Yes, LeisterTech offers custom-built sintering heaters to fit your specific operational needs, ensuring maximum efficiency and performance.

What kind of power source is needed for the sintering heater?

The sintering heater requires a dedicated power panel, which is provided by LeisterTech, to control and regulate the heating process.

Can the sintering heater be used in other applications besides ramming mass?

While primarily designed for ramming mass sintering, the heater can be customized for other high-temperature processes where uniform and efficient heating is required.

What is the lifespan of a LeisterTech sintering heater?

Built with high-quality materials like Ni-Cr strips, our sintering heaters are durable and require minimal maintenance, ensuring long-lasting performance.

How do I know if the sintering heater is the right choice for my operations?

Our team at LeisterTech will work with you to understand your needs and recommend the best solution. Contact us for a consultation.