Grab Buckets

Precision Handling for Industrial Applications

LeisterTech proudly offers a comprehensive range of grab buckets, designed to meet the demanding needs of industrial material handling. Our grab buckets are engineered for efficiency, durability, and precision, making them essential tools for industries such as steel, mining, construction, and waste management.

What are Grab Buckets?

Grab buckets are specialized mechanical tools used for lifting and transporting bulk materials. These buckets are widely employed in industries for handling a variety of materials, including core scrap, pig-iron, stones, slag, baled scrap, green pellets, and more. With robust construction and advanced hydraulic systems, LeisterTech’s grab buckets are built to withstand tough working conditions while ensuring maximum efficiency.

LeisterTech Grab Buckets offer versatile designs, durable steel, high load capacity, and advanced hydraulics for efficient, low-maintenance operation.

Versatile Design Options

High-Quality Materials

Optimized Geometry

Robust Structure

Advanced Hydraulic Systems

Maintenance-Free Operation

ISO Certified

LeisterTech offers a diverse range of grab buckets, each tailored to specific industrial applications:

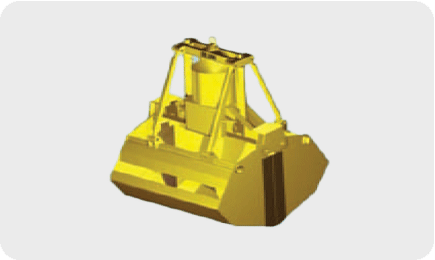

Clamshell Grab Bucket

Application: The Electro Hydraulic double scoop Clamshell grab is designed for handling and discharging bulk materials like scrap and DRI at ports.

Features: Provides excellent control and precision, making it suitable for both light and heavy-duty tasks.

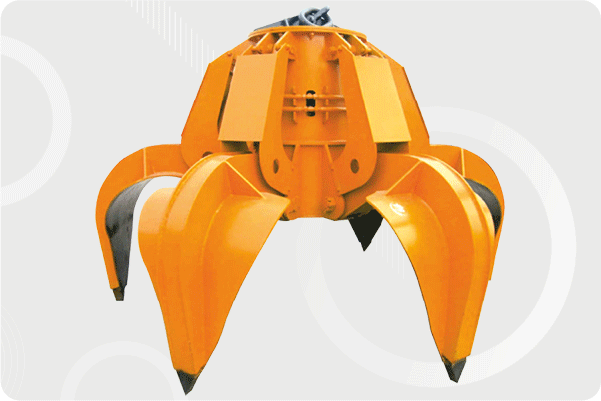

Orange Peel Grab Bucket

Application: Used for handling irregularly shaped materials such as scrap metal, rocks, and debris.

Features: The multi-tine design ensures a secure grip on various types of bulk materials.

Log Grab Bucket

Application: Specifically designed for lifting and transporting wooden logs.

Features: Equipped with sturdy jaws and a robust hydraulic system for efficient log handling.

Excavator Grab Bucket

Application: Attached to excavators for digging and material handling in construction, mining and scrap handling.

Features: Provides powerful gripping force, making it ideal for heavy-duty excavation tasks.

Four Rope Grab Bucket

Application: Commonly used in ports and shipyards for handling bulk materials.

Features: Operates with four ropes for enhanced stability and control during lifting operations.

Mill Scale Grab Bucket

Application: Designed for handling mill scale, slag, and other by-products in steel mills.

Features: Built to withstand abrasive materials.

| Size 1 | Capacity 2 | Dead Weight Grab | Crane | Motor | Intensity 400V | Operating Pressure | Closing Time | Opening Time | Overall Dimensions mm. | Number of Shells | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volume | Load Medium | 3 | 4 | 5 | 6 | |||||||||

| M3 | t | Kg | t | Kw | A | Bars | S" | S" | A | B | C | D | ||

| LT-500 | 0,5 | 1 - 1,4 | 1.600 | 3 | 10 | 20 | 160 | 8 | 4 | 1080 | 1731 | 1550 | 2372 | 5 |

| LT-750 | 0,75 | 1,5 - 1,9 | 1.785 | 4 | 10 | 20 | 160 | 8 | 4 | 1910 | 1700 | 1750 | 2560 | 5 |

| LT-1000 | 1 | 2,2 - 2,5 | 1.925 | 4,5 | 20,5 | 39 | 200 | 8 | 4 | 2060 | 1750 | 1980 | 2700 | 5 |

| LT-1250 | 1,25 | 2,5 - 2,8 | 2.015 | 5 | 20,5 | 39 | 200 | 8.5 | 4.5 | 2260 | 1810 | 2000 | 2980 | 5 |

| LT-1600 | 1,6 | 2,7 - 3,4 | 2.300 | 5,5 | 25,5 | 48,5 | 250 | 8,5 | 4,5 | 2530 | 2075 | 2300 | 3120 | 6 |

| LT-1750 | 1,75 | 2,9 - 3,6 | 2.412 | 6 | 31,5 | 61 | 250 | 8,5 | 4,5 | 2566 | 2115 | 2138 | 3456 | 6 |

| LT-2000 | 2 | 3 - 4 | 2.992 | 6,5 | 31,5 | 61 | 250 | 8,5 | 4,5 | 2633 | 2160 | 2425 | 3315 | 6 |

| LT-2250 | 2,25 | 3,3 - 4,4 | 3.390 | 8,7 | 31,5 | 61 | 225 | 9 | 5 | 2740 | 2200 | 2505 | 3500 | 6 |

| LT-2500 | 2,5 | 3,7 - 4,8 | 4.690 | 9,4 | 31,5 | 61 | 225 | 9 | 5 | 2773 | 2260 | 2585 | 3600 | 6 |

| LT-2750 | 2,75 | 4,1 - 6 | 4.990 | 10,9 | 31,5 | 61 | 225 | 9,5 | 5,5 | 2953 | 2510 | 2605 | 3807 | 6 |

| LT-3000 | 3 | 4,4 - 6,2 | 5.030 | 11,2 | 40 | 74,5 | 250 | 9,5 | 5,5 | 3065 | 2550 | 2620 | 4005 | 6 |

| LT-3200 | 3,2 | 5 - 7 | 5.150 | 12,1 | 40 | 74,5 | 250 | 9,5 | 5,5 | 3200 | 2719 | 2637 | 4023 | 6 |

Technical Advantages of LeisterTech Grab Buckets

Enhanced Visibility

Reduced Platform Wear

Improved MTTR

Lower Dead Weight

Increased Efficiency

Energy Efficient

Safety in Power Outages

Non-Ferrous Handling

LeisterTech is committed to delivering high-quality, reliable material handling solutions. Our grab buckets are the result of extensive research and development, ensuring they meet the highest standards of performance and durability. Whether you need to handle bulk materials, scrap, or specific industrial by-products, LeisterTech has the perfect grab bucket to meet your requirements.

Find quick answers to common questions about Grab Buckets.

What materials can LeisterTech grab buckets handle?

LeisterTech grab buckets are designed to handle a wide range of materials, including core scrap, pig-iron, stones, slag, baled scrap, green pellets, and more.

What are the benefits of using grab buckets over electromagnets?

Grab buckets offer several advantages over electromagnets, including reduced platform wear, lower dead weight, higher efficiency, and the ability to handle non-ferrous materials.

Are LeisterTech grab buckets easy to maintain?

Yes, our grab buckets are designed for minimal maintenance, with features like fully protected hydraulic cylinders and maintenance-free operation.

What types of grab buckets does LeisterTech offer?

LeisterTech offers various types of grab buckets, including clamshell, orange peel, log, excavator, four rope, and mill scale grab buckets.

How do grab buckets enhance operational efficiency?

Grab buckets can handle larger volumes of material compared to electromagnets, consume less power, and offer precise material handling, all of which contribute to increased operational efficiency.

Are LeisterTech grab buckets suitable for heavy-duty applications?

Yes, our grab buckets are constructed from high-strength materials and are designed to withstand heavy-duty applications in industries such as steel, mining, and construction.

How do grab buckets improve safety in material handling?

Grab buckets eliminate the risks associated with electromagnets, such as insulation failure and power outages, making them a safer option for material handling.