Hot Billet Shearing

Precision Cutting for Continuous Operations

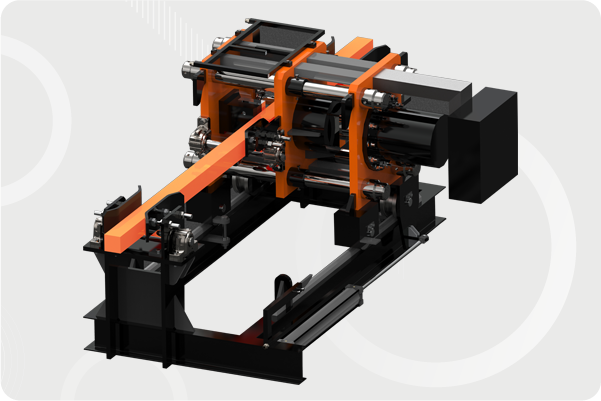

LeisterTech's Hot Billet Shearing Machine is a state-of-the-art solution designed to enhance the efficiency and safety of steel plant operations. This advanced system automatically cuts billets to specific lengths, streamlining the process of transferring billets within the plant, whether it’s in a Steel Melting Shop (SMS), Continuous Casting Machine (CCM), or Rolling Mills. The Hot Billet Shearing Machine is an essential tool for maintaining continuous operations and optimizing productivity.

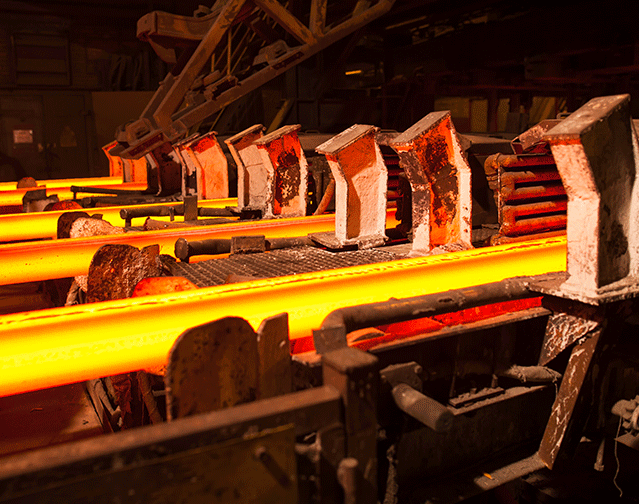

What is Hot Billet Shearing?

Hot Billet Shearing refers to the process of cutting hot billets—square or rectangular pieces of metal—into predetermined lengths while they are still hot from the production process. This is crucial for the seamless transfer of billets from one stage of production to another, ensuring that they are of the appropriate size for subsequent processes or transportation.

LeisterTech Hot Billet Shearing Machine offers precise automatic cutting, versatile hydraulic shearing, seamless integration, enhanced safety, and durable construction for efficient steel plant operations.

Automatic Precision Cutting

Hydraulic Horizontal and Vertical Cutting

Continuous Operation Support

Safety and Efficiency

Durable and Reliable Construction

Advanced Control System

The Hot Billet Shearing Machine is essential in various stages of steel production, particularly in:

Steel Melting Shops (SMS)

Cutting billets to the required length for further processing.

Rolling Mills

Preparing billets for rolling into finished products by cutting them to the appropriate length.

Continuous Casting Machines (CCM)

Ensuring billets are the correct size for smooth transfer and handling.

Transportation and Storage

Facilitating the transfer and storage of billets by cutting them to manageable sizes.

Advantages of LeisterTech’s Hot Billet Shearing Machine

Enhanced Safety

Increased Productivity

Cost-Effective Operation

Flexibility and Adaptability

Precision and Reliability

Enhanced Safety Measures

Optimized Energy Consumption

Customizable Solutions

Find quick answers to common questions about Hot Billet Shearing.

What types of billets can the Hot Billet Shearing Machine handle?

The Hot Billet Shearing Machine is designed to handle various sizes and shapes of billets, making it suitable for different stages of steel production.

How does the machine improve safety in the plant?

By automating the cutting process, the machine reduces the need for manual handling, minimizing the risks of burns, gas exposure and other injuries associated with billet cutting.

Can the machine be integrated into existing production lines?

Yes, the Hot Billet Shearing Machine is designed for seamless integration into existing production lines, ensuring minimal disruption to your operations.

What are the benefits of hydraulic cutting over manual cutting?

Hydraulic cutting provides more precise, consistent, and faster cuts than manual methods. It also reduces operator fatigue and enhances safety by minimizing direct human interaction with hot billets.

How does the machine optimize energy consumption?

The Hot Billet Shearing Machine is designed with energy efficiency in mind, optimizing the use of power and gas to reduce operational costs while maintaining high productivity levels.

What maintenance is required for the Hot Billet Shearing Machine?

The machine requires minimal maintenance due to its durable construction. Regular inspections and routine maintenance will keep it operating efficiently.

Is the machine customizable for specific plant requirements?

Yes, LeisterTech offers customization options to ensure the Hot Billet Shearing Machine meets the specific needs of your plant, providing a solution that is tailored to your production processes.