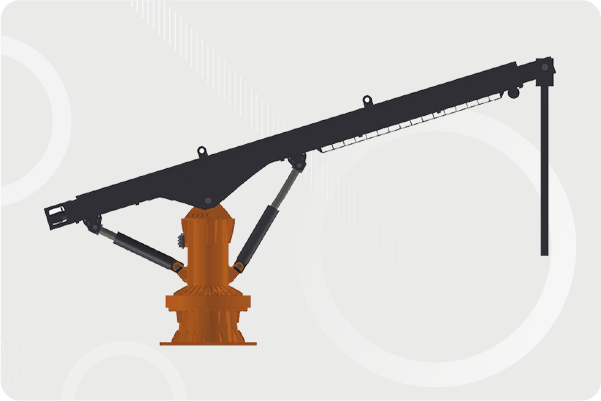

Hydraulic Pusher

Revolutionizing Furnace Operations with Efficiency and Safety

LeisterTech’s Hydraulic Pusher is a cutting-edge solution designed to enhance the efficiency, safety, and productivity of induction furnace operations. This innovative system is engineered to minimize manual labor, optimize scrap density within the furnace, and maximize the melting process, making it an indispensable tool for iinduction furnaces.

What is a Hydraulic Pusher?

A Hydraulic Pusher is a specialized device used in induction furnaces to push and manipulate scrap metal. By automating the process of feeding scrap into the furnace, the Hydraulic Pusher eliminates the need for manual intervention, reducing the risks associated with high-temperature environments and improving the overall efficiency of the melting process.

LeisterTech Hydraulic Pusher enhances furnace operations with efficient scrap density optimization, reduced manual labor, and improved melting processes.

Innovative and Rugged Design

Increased Scrap Density

Full Space Occupation

Electro-Hydraulic Operation

Safety and Operator Comfort

High Melting Rate

Labor and Production Efficiency

Enhanced Furnace Utilization

Improved Safety for Operators

Higher Production Output

Reduced Manual Labor

The Hydraulic Pusher is used across various metalworking industries for the efficient handling and melting of different types of scrap. Key applications include:

Steel Plants

Find quick answers to common questions about Hydraulic Pusher.

What types of scrap can the Hydraulic Pusher handle?

The Hydraulic Pusher is designed to handle a wide range of scrap materials, including steel, iron, copper, aluminum, and other metal scraps commonly used in induction furnaces.

How does the Hydraulic Pusher improve safety in the workplace?

The Hydraulic Pusher keeps operators at a safe distance from the furnace, reducing their exposure to extreme heat, fumes, and molten metal splatters. This significantly enhances workplace safety.

Can the Hydraulic Pusher be customized for specific furnace sizes?

Yes, LeisterTech offers customization options for the Hydraulic Pusher to ensure it fits the specific requirements of your furnace and operations, providing optimal performance.

What maintenance is required for the Hydraulic Pusher?

The Hydraulic Pusher is designed for minimal maintenance, with durable components that ensure long-lasting performance. Regular inspections and routine maintenance will keep the system operating efficiently.

How does the Hydraulic Pusher reduce labor costs?

By reducing the need for manual labor in the scrap feeding process, the Hydraulic Pusher allows operators to focus on other critical tasks, decreasing labor costs and improving overall efficiency.

How does the Hydraulic Pusher increase production efficiency?

By automating the scrap feeding process and increasing the density of scrap in the furnace, the Hydraulic Pusher reduces the number of cycles needed per batch, leading to higher production output.