Lifting Magnets

Efficient and Safe Material Handling Solutions

LeisterTech specializes in designing and manufacturing high-performance lifting magnets that are integral to various industries, including foundries, steel plants, and scrap yards. Our lifting magnets are engineered to provide reliable and efficient handling of ferrous materials, ensuring safety and productivity in demanding industrial environments.

What are Lifting Magnets?

Lifting magnets are electromagnets designed to lift and transport ferrous materials. These powerful tools are essential for handling heavy metal objects such as scrap, billets, bundles, and rails. By creating a strong magnetic field, lifting magnets can securely pick up and move metal objects without the need for physical contact, reducing the risk of damage and increasing operational efficiency.

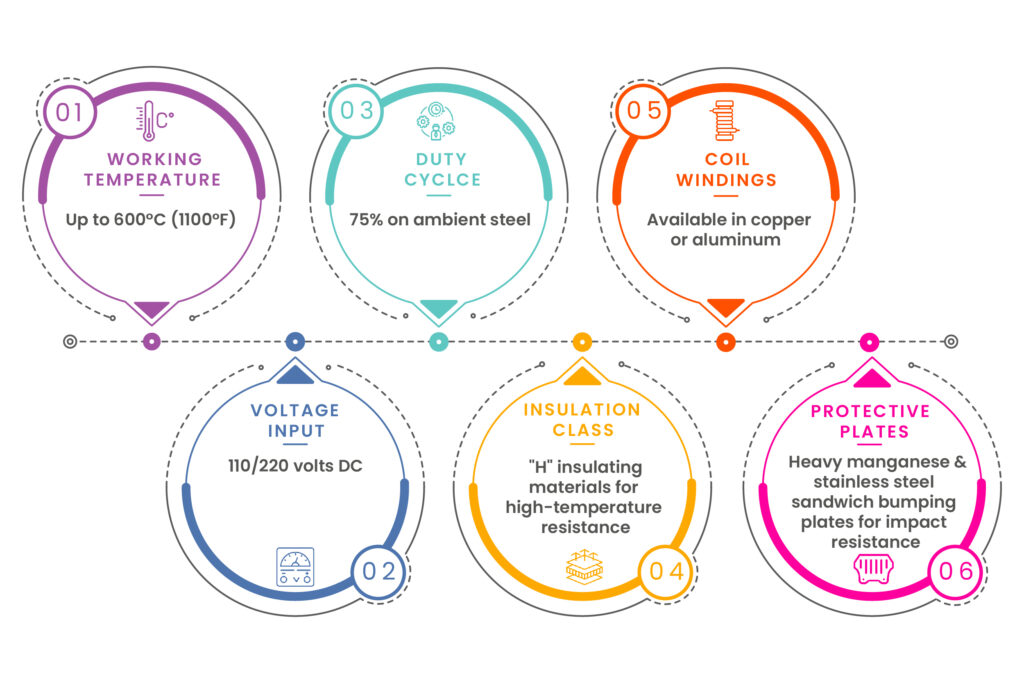

The key features of LeisterTech lifting magnets include robust construction, high magnetic strength, energy efficiency, and easy operation for safe and reliable material handling in industrial environments.

Heavy-Duty Construction

Class C/H Insulation

High Duty Cycle

Customizable Designs

Temperature Resistance

Advanced Materials

Energy Efficient

LeisterTech offers a variety of lifting magnets, each suited to different industrial applications:

Circular Lifting Magnets

Application: Ideal for handling scrap in foundries, steel plants, and scrap yards.

Features: Designed for heavy-duty operations, these magnets provide reliable lifting power and are built to withstand the rigors of industrial use.

Rectangular Lifting Magnets

Application: Used for lifting billets, bundles, and rails in steel mills.

Features: Customizable sizes and configurations to meet specific application requirements, with welded, fabricated designs for added strength.

Overband Magnetic Separator

Application: Used to separate tramp iron from conveyor belts in industries such as mining and recycling, cement, coal industries, salt industries etc.

Features: Oil-cooled or air-cooled separators remove tramp iron particles.

Electro Suspension Magnetic Separator

Application: Suspended above conveyor belts to attract and remove ferrous particles from materials being transported.

Features: Provides effective separation and can be easily deactivated when not in use, offering flexibility in operation.

| Model No. | KW |

Approx.

Weight of the Magnet in KG +/- 5% |

Diameter of Magnet +/- 50MM |

Required Minimum Crane Capacity in MT |

|---|---|---|---|---|

| LT135 CM | 10.5 | 2200 | 1350 | 5 |

| LT165 CM | 16 | 4500 | 1650 | 10 |

| LT185 CM | 20 | 5800 | 1850 | 10/15 |

| LT185 CM | 24 | 6000 | 1850 | 10/15 |

| LT215 CM | 32 | 10000 | 2150 | 20/25 |

| LT215 CM | 40 | 11000 | 2150 | 20/25 |

Advantages of Using LeisterTech Lifting Magnets

Increased Safety

Damage Prevention

Remote Operation

Energy Savings

Scrap Handling

Billet and Bundle Handling

Rail Handling

Tramp Iron Separation

Find quick answers to common questions about Lifting Magnets.

What industries benefit from using LeisterTech lifting magnets?

Industries such as steel plants, foundries, scrap yards, and recycling facilities benefit from the efficiency and safety provided by LeisterTech lifting magnets.

What is the duty cycle of LeisterTech lifting magnets?

Our lifting magnets have a 75% duty cycle, allowing them to operate for 7.5 minutes on and 2.5 minutes off within a 10-minute cycle.

Can LeisterTech customize lifting magnets for specific applications?

Yes, LeisterTech offers customizable lifting magnets to meet the unique requirements of each customer, including different sizes, shapes, and configurations.

What temperatures can LeisterTech lifting magnets withstand?

Our lifting magnets are designed to withstand working temperatures of up to 600°C (1100°F), making them suitable for high-temperature environments.

How do LeisterTech lifting magnets improve safety in the workplace?

LeisterTech lifting magnets reduce the need for manual handling of heavy materials, minimizing the risk of workplace injuries and accidents. Additionally, operators can control the magnets remotely, enhancing operational safety.

What are the energy efficiency benefits of using LeisterTech lifting magnets?

Our lifting magnets operate on a low voltage (110/220 volts DC), consuming less energy compared to other material handling equipment. This not only reduces operational costs but also contributes to environmental sustainability.

How do LeisterTech's magnetic separators work?

LeisterTech's magnetic separators attract ferrous particles suspended above conveyor belts. The tramp iron is lifted from the conveyor and separated through a self-cleaning method, ensuring continuous operation and reducing contamination in the final product.