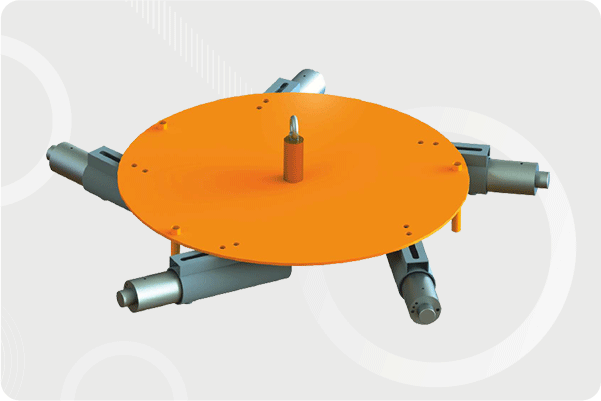

Lining Vibrator

Revolutionizing Furnace Lining for Enhanced Performance

At LeisterTech our Lining Vibrators are engineered to offer superior reliability and efficiency in the industrial furnace lining process. This advanced technology is designed to optimize the lining of high-temperature furnaces, ensuring uniformity, durability, and enhanced performance, ultimately leading to improved operational efficiency and reduced downtime.

What is a Lining Vibrator?

A lining vibrator is a specialized tool used in the preparation of refractory linings in induction furnaces. These vibrators ensure that the lining material is compacted uniformly, eliminating any voids or air pockets that could compromise the integrity of the lining. Properly compacted linings extend the life of the furnace and improve its performance, making lining vibrators essential for industries that rely on high-temperature furnaces, such as steel production, foundries, and metal processing.

We specializes in a diverse range of services and products designed to cater to various industrial sectors.

Uniform Compaction

Advanced Vibration Technology

Durability and Reliability

Customizable Options

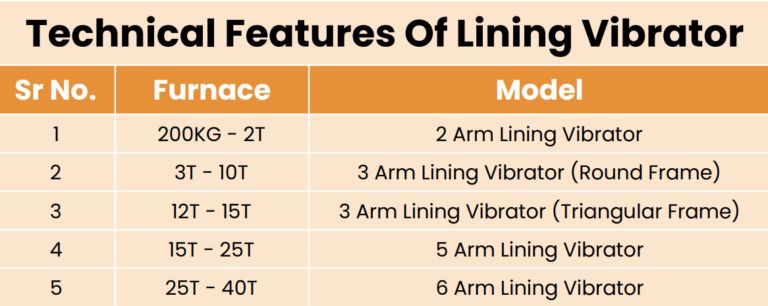

LeisterTech offers a range of lining vibrator models to cater to various furnace sizes and industrial needs

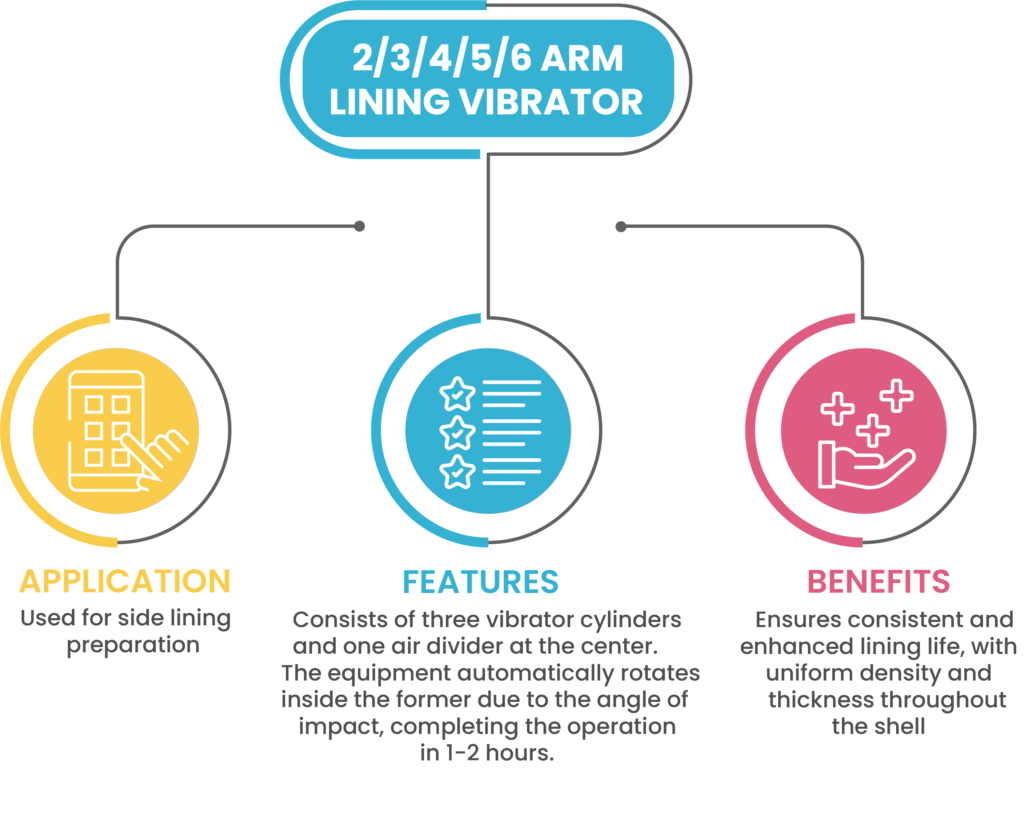

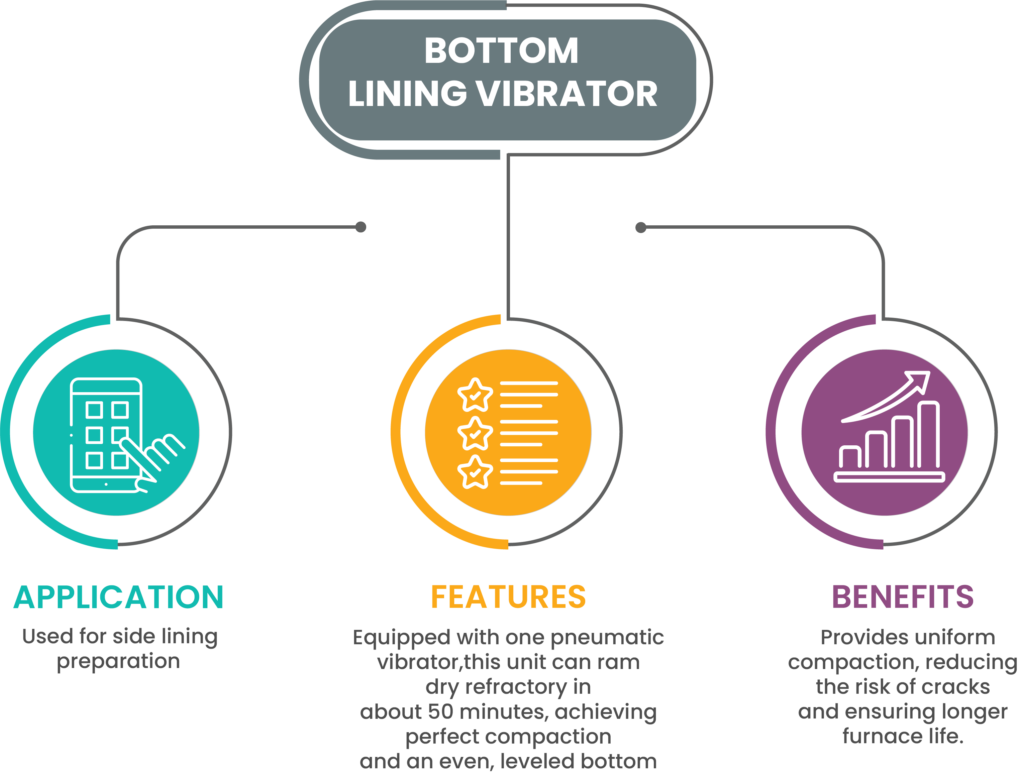

LeisterTech provides two primary types of lining vibrators, each designed to address different aspects of the furnace lining process:

Lining with a vibrator offers more consistent compaction and durability compared to the manual method, which can be uneven and labor-intensive.

MANUAL LINING

- Erratic and shorter lining life.

- Unpredictable production.

- Density of Lining is not uniform.

- Lining thickness is not uniform around the former.

- Refractory material in the tapered Section of the former is not completely deaerated leading to non-uniform erosion of lining and problems like elephant foot & leakage.

LINING USING LINING VIBRATOR

- Consistent and enhanced lining life. Predictable and increased total output tonnage.

- Density of lining is uniform throughout the shell.

- Lining thickness is absolutely uniform around the former.

- Material in the tapered section of the former is completely dense achieving max. & uniform compaction. Thus erosion is uniform in the tapered section eliminating any possibility of elephant foot & leakage due to weak lining.

Advantages of Using LeisterTech Lining Vibrators

Enhanced Lining Life

Improved Furnace Performance

Predictable Production

Reduced Maintenance Costs

Find quick answers to common questions about Lining Vibrator.

What is the primary function of a lining vibrator?

A lining vibrator is used to ensure the uniform compaction of refractory materials in industrial furnaces, which is crucial for the durability and efficiency of the furnace lining.

How does a lining vibrator improve furnace performance?

By ensuring that the refractory lining is compacted uniformly, a lining vibrator reduces the risk of cracks and premature failure, leading to better thermal efficiency and consistent furnace performance.

What are the different models of lining vibrators offered by LeisterTech?

LeisterTech offers several models, including the SM01 to SM06, each designed for different furnace capacities ranging from 300 Kg to 50T.

How long does it take to complete the lining process using LeisterTech’s vibrators?

The time required varies depending on the type of vibrator used. For example, the 3/2 arm lining vibrator completes the operation in 1-2 hours, while the bottom lining vibrator can finish the ramming process in about 50 minutes.

Can LeisterTech’s lining vibrators be customized?

Yes, LeisterTech offers customizable options for their lining vibrators to meet the specific needs of different furnace types and capacities.

What is the difference between Side lining vibrators and bottom lining vibrators?

The side lining vibrators are used for side lining preparation, while bottom lining vibrators are designed specifically for compacting the bottom lining of the furnace.