The integration of smart technologies like IoT (Internet of Things), AI (Artificial Intelligence), and machine learning is revolutionizing industrial machinery, driving the shift towards Industry 4.0. These technologies enable intelligent, data-driven systems that enhance productivity, precision, and efficiency while reducing operational costs.

The Role of IoT in Industrial Machinery

Precision engineering involves designing and manufacturing machinery that operates with exceptionally high accuracy and minimal tolerances. It is essential in industries like steel production, automotive manufacturing, and material handling, where even minor deviations can lead to inefficiencies or quality issues.

Key characteristics of precision engineering include:

Tight Tolerances

Durability and Reliability

Automation Integration

How LeisterTech’s Machines Excel in Precision

1.Hydraulic Pushers

LeisterTech’s hydraulic pushers are engineered for applications requiring controlled force and precision.

- High Load Accuracy: Integrated smart sensors ensure consistent force application, reducing variability.

- Smooth Operation: Advanced hydraulic systems minimize vibration and maintain stability during operations.

- Reduced Wear: The use of high-quality materials and precision engineering extends the lifespan of components, minimizing downtime.

2.Hot Billet Shearing Machines

These machines are crucial for cutting steel billets with exacting accuracy.

- Temperature Control: Smart technology adjusts blade speed and temperature based on material properties, ensuring clean cuts.

- Robust Blades: Precision-crafted blades resist wear, maintaining sharpness and reducing the need for frequent replacements.

- Consistent Performance: Advanced mechanics ensure uniform shearing even under high production demands.

3.Lining Vibrators

Designed to enhance the consistency of lining in molds, LeisterTech’s vibrators achieve uniform distribution of materials.

- Controlled Amplitude: Adjustable settings enable precise control over vibration intensity for different materials.

- Efficient Energy Use: Smart systems optimize power usage without compromising performance.

Advantages of Precision Engineering for Manufacturers

Improved Product Quality

Precision tools ensure uniformity, reducing defects and maintaining high-quality standards.

Increased Efficiency

Accurate machinery minimizes material waste, optimizes resource use, and reduces cycle times.

Enhanced Safety

Precision engineering ensures predictable machine behavior, reducing risks associated with human error or equipment malfunction.

Lower Operational Costs

Durability and efficiency reduce maintenance costs, downtime, and energy consumption.

The Role of Advanced Technologies

LeisterTech integrates cutting-edge technologies to enhance the precision of their equipment:

IoT Integration

AI-Driven Adjustments

Smart Sensors

Applications in Modern Manufacturing

LeisterTech’s precision machinery supports diverse industries:

Steel Production

Hydraulic pushers and shearing tools are used to process high-strength materials with exacting tolerances.

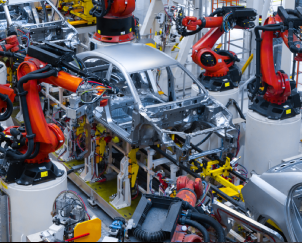

Automotive Manufacturing

Precision-engineered components ensure the reliability of critical systems frames and suspensions.

Foundries

Vibrators and material handling tools streamline processes consistent mold quality and reduced waste.

LeisterTech’s dedication to precision engineering meets the ever-increasing demands of modern manufacturing. Their advanced machines not only deliver accuracy and reliability but also set new standards for efficiency and sustainability. For manufacturers aiming to achieve superior quality and performance, LeisterTech’s precision solutions are a game-changer.

lpipl

lpiplYou Might Also Like

- lpipl

- 0 Comments

- lpipl

- 0 Comments

- lpipl

- 0 Comments