As industries strive for greater efficiency and sustainability, innovations in material handling equipment are transforming the landscape of scrap and bulk material management. These advancements not only optimize recycling processes but also enhance waste management, making operations more efficient and environmentally friendly. This article highlights the latest trends and technologies in material handling equipment and their role in optimizing recycling and waste management.

1. Automation and Robotics

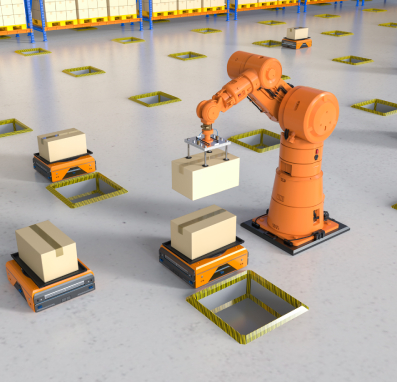

Automation is one of the most significant advancements in material handling. The integration of robotics and automated systems in scrap and bulk material handling has revolutionized operations. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are increasingly employed to transport materials within facilities, minimizing human labor and improving safety. These systems can efficiently navigate complex environments, enabling real-time tracking and optimized routing.

For example, companies like KUKA and Dematic are leading the charge in robotic automation, offering systems designed to handle diverse materials, from heavy scrap metal to lightweight packaging Leistertech Projects

Leistertech Projects Such innovations enhance operational efficiency, reduce labor costs, and allow for better inventory management.

2. Advanced Sorting Technologies

Effective recycling and waste management depend heavily on sorting technologies. The latest innovations in sensor-based sorting systems, including artificial intelligence (AI) and machine learning, enable more precise identification and separation of materials. These systems can analyze various materials based on their properties, such as size, shape, and composition, leading to higher recovery rates of recyclables.

For instance, companies like ZenRobotics and Tomra have developed AI-powered sorting solutions that increase the efficiency and accuracy of waste sorting, significantly improving recycling rates and reducing contamination Leistertech projects

Leistertech Projects These technologies help facilities handle bulk waste more effectively by automating the sorting process, leading to better resource recovery.

3. Enhanced Material Handling Equipment

The latest designs in material handling equipment focus on durability, efficiency, and ease of use. Innovations such as telehandlers and heavy-duty forklifts equipped with advanced hydraulic systems and ergonomic designs improve the handling of bulk materials. These machines offer higher lifting capacities and greater maneuverability, essential for managing heavy scrap and bulk materials in recycling facilities and construction sites.

Moreover, companies are investing in electric and hybrid-powered equipment to reduce emissions and energy consumption. According to the Material Handling Industry of America (MHIA), transitioning to electric forklifts can reduce operational costs and carbon footprints significantly Leistertech Projects

4. Data Analytics and IoT Integration

The integration of the Internet of Things (IoT) and data analytics is transforming material handling operations. By equipping handling equipment with sensors, companies can gather real-time data on equipment performance, material flow, and inventory levels. This data can then be analyzed to identify bottlenecks, predict maintenance needs, and optimize overall operations.

For example, Siemens and Honeywell provide IoT-enabled material handling solutions that offer insights into operational efficiency, enabling companies to make informed decisions and improve resource utilization . This level of data-driven decision-making is essential for maximizing the efficiency of recycling processes and waste management strategies.

As environmental concerns continue to rise, sustainability initiatives are at the forefront of advancements in material handling equipment. Many companies are designing equipment with a focus on reducing energy consumption and waste generation. This includes innovations in recycling machinery that minimize energy usage and maximize material recovery. For instance, Caterpillar and Komatsu are implementing sustainable practices in their machinery design and production processes, emphasizing the use of recyclable materials and energy-efficient technologies . These efforts not only help companies meet regulatory requirements but also enhance their brand reputation among environmentally conscious consumers.

Conclusion

The future of material handling is being shaped by innovative technologies that enhance efficiency, safety, and sustainability in scrap and bulk material management. As industries increasingly prioritize recycling and waste management, advancements in automation, sorting technologies, material handling equipment, and data analytics are crucial for optimizing operations.

By adopting these innovations, companies can improve their resource recovery rates, reduce costs, and contribute to a more sustainable future. As the demand for efficient material handling solutions continues to grow, staying ahead of these trends will be essential for businesses looking to thrive in an evolving marketplace.

- KUKA Robotics

- Dematic

- ZenRobotics

- Tomra Sorting

- Material Handling Industry of America

- Siemens IoT Solutions

- Honeywell Connected Solutions

lpipl

lpiplYou Might Also Like

- lpipl

- 0 Comments

- lpipl

- 0 Comments

- lpipl

- 0 Comments