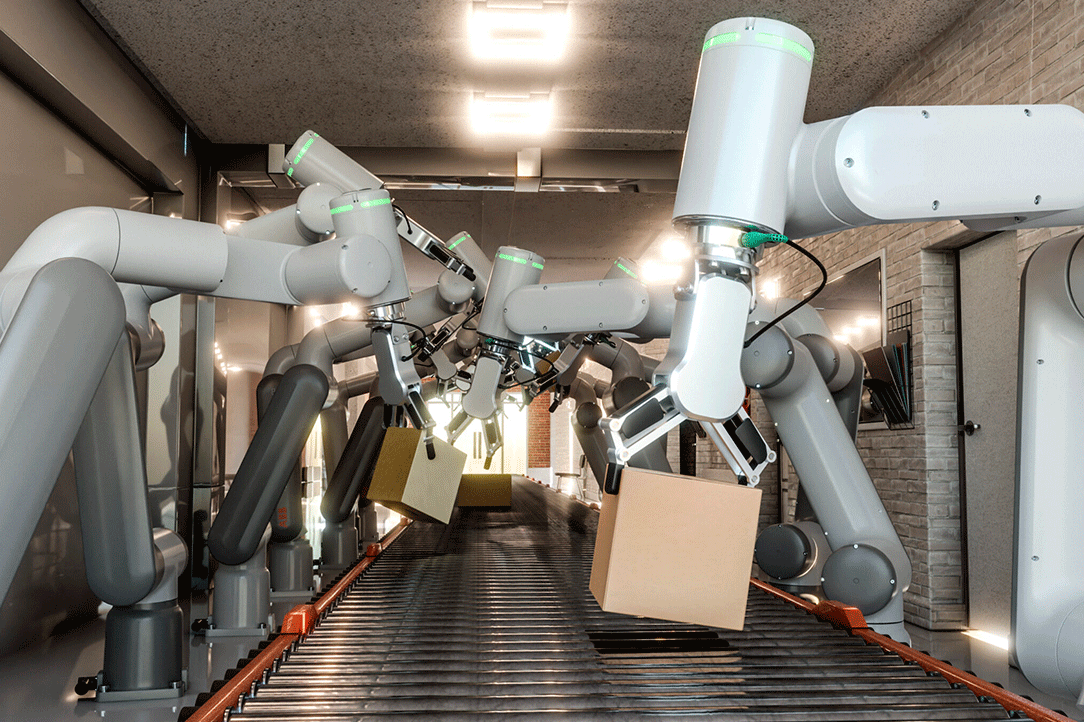

The landscape of industrial production is undergoing a profound transformation, driven by the rapid advancement of automation technologies. Automation is revolutionizing the manufacturing sector by enhancing efficiency, precision, and productivity. As industries embrace these technological innovations, they are unlocking new levels of performance and competitive advantage. In this blog, we will explore the pivotal role of automation in modern industrial production and highlight how LeisterTech is integrating these cutting-edge technologies into its machinery.

The Rise of Automation in Manufacturing

Automation involves the use of control systems—such as computers, robots, and other technologies—to manage and operate machinery, processes, and systems. The integration of automation into manufacturing processes has led to several key advancements:

1. Increased Efficiency and Productivity

Automation systems are designed to streamline production processes, reducing the time and effort required to complete tasks. Automated machinery operates at a consistent speed and with high precision, significantly increasing production rates and output.

Benefits:

- Enhanced Throughput: Automated systems can operate 24/7 without breaks, leading to higher production volumes.

- Consistent Quality: Automation minimizes human error, ensuring uniform product quality and reducing the likelihood of defects.

- Faster Production Cycles: Automated processes accelerate production cycles, enabling faster time-to-market for new products.

LeisterTech’s commitment to automation is evident in its advanced machinery, such as the Lining Vibrator and Hot Billet Shearing Machine. These products incorporate automated features to boost production efficiency and maintain high-quality standards.

2. Precision and Accuracy

Modern automation technologies enable unparalleled precision and accuracy in manufacturing processes. Automated systems are capable of performing repetitive tasks with exceptional consistency, ensuring that each product meets stringent specifications.

Benefits:

- Reduced Variability: Automation reduces variability in manufacturing processes, leading to more consistent and reliable results.

- Improved Tolerance Levels: Automated equipment can achieve tighter tolerances and finer details, enhancing product quality.

- Error Reduction: Automation minimizes the risk of human error, resulting in fewer defects and rework.

LeisterTech’s engineering excellence is reflected in products like the Grab Buckets and Baling Press, which feature precision-driven automation to deliver accurate and high-quality performance in demanding environments.

3. Enhanced Safety and Ergonomics

Automation plays a crucial role in improving workplace safety and ergonomics. By taking over hazardous or physically demanding tasks, automated systems reduce the risk of injury and strain for human operators.

Benefits:

- Safer Work Environments: Automation reduces the need for human intervention in dangerous or high-risk tasks, promoting a safer work environment.

- Ergonomic Benefits: Automated systems handle repetitive and physically strenuous tasks, reducing the risk of musculoskeletal disorders among workers.

- Reduced Human Error: Automation decreases the likelihood of accidents caused by human error, enhancing overall safety.

LeisterTech’s approach to safety is integrated into its machinery, such as the Hydraulic Pusher and Lifting Magnets, which are designed with automation features that prioritize operator safety and ergonomic comfort.

4. Data-Driven Insights and Optimization

Automation technologies generate valuable data that can be used to monitor and optimize production processes. By analyzing data from automated systems, manufacturers can gain insights into performance, identify areas for improvement, and make informed decisions.

Benefits:

- Real-Time Monitoring: Automated systems provide real-time data on production performance, allowing for timely adjustments and optimization.

- Predictive Maintenance: Data-driven insights enable predictive maintenance, reducing unplanned downtime and extending equipment lifespan.

- Process Optimization: Analysis of production data helps identify inefficiencies and optimize processes for better overall performance.

LeisterTech’s integration of automation extends to data collection and analysis features, allowing customers to leverage insights for continuous improvement and operational excellence.

5. Flexibility and Scalability

Automation systems offer flexibility and scalability, enabling manufacturers to adapt to changing production demands and market conditions. Automated machinery can be reconfigured or scaled up to accommodate new products or increased production volumes.

Benefits:

- Adaptability: Automated systems can be adjusted to handle different products or production requirements, providing flexibility in manufacturing.

- Scalability: Automation allows for easy scaling of production processes to meet growing demand without significant changes to infrastructure.

- Efficient Resource Utilization: Automation optimizes resource usage, reducing waste and improving overall efficiency.

LeisterTech’s range of products, such as the Stationary Cranes and Ladle Transfer Trolley, are designed with scalability and adaptability in mind, supporting a wide range of manufacturing needs and growth opportunities.

LeisterTech’s Commitment to Automation

LeisterTech is at the forefront of integrating automation into its machinery, delivering innovative solutions that enhance productivity, precision, and safety. The company’s products are designed with advanced automation features that align with the latest industry trends and technological advancements

Key Aspects of LeisterTech’s Automation Integration:

- Advanced Control Systems: LeisterTech incorporates sophisticated control systems into its machinery, providing seamless automation and real-time monitoring.

- Customizable Solutions: The company offers customizable automation solutions to meet specific manufacturing requirements and production goals.

- Ongoing Innovation: LeisterTech continuously invests in research and development to stay ahead of automation trends and deliver cutting-edge solutions to its customers.

By embracing automation, manufacturers can achieve significant improvements in efficiency, quality, and safety. LeisterTech’s dedication to integrating automation into its machinery ensures that customers benefit from the latest technological advancements and remain competitive in a rapidly evolving industry.

Conclusion

Automation is transforming modern industrial production by driving efficiency, precision, and productivity. As manufacturing processes become increasingly automated, businesses can leverage these technologies to achieve greater operational success and stay ahead of industry trends. LeisterTech’s integration of automation into its machinery exemplifies the benefits of these advancements, providing customers with innovative solutions that enhance performance and support long-term growth.

Embrace the future of industrial production with automation and discover the advantages of advanced technology in your manufacturing operations. With LeisterTech’s cutting-edge machinery and automation solutions, you can achieve new levels of efficiency, quality, and success in your production processes.