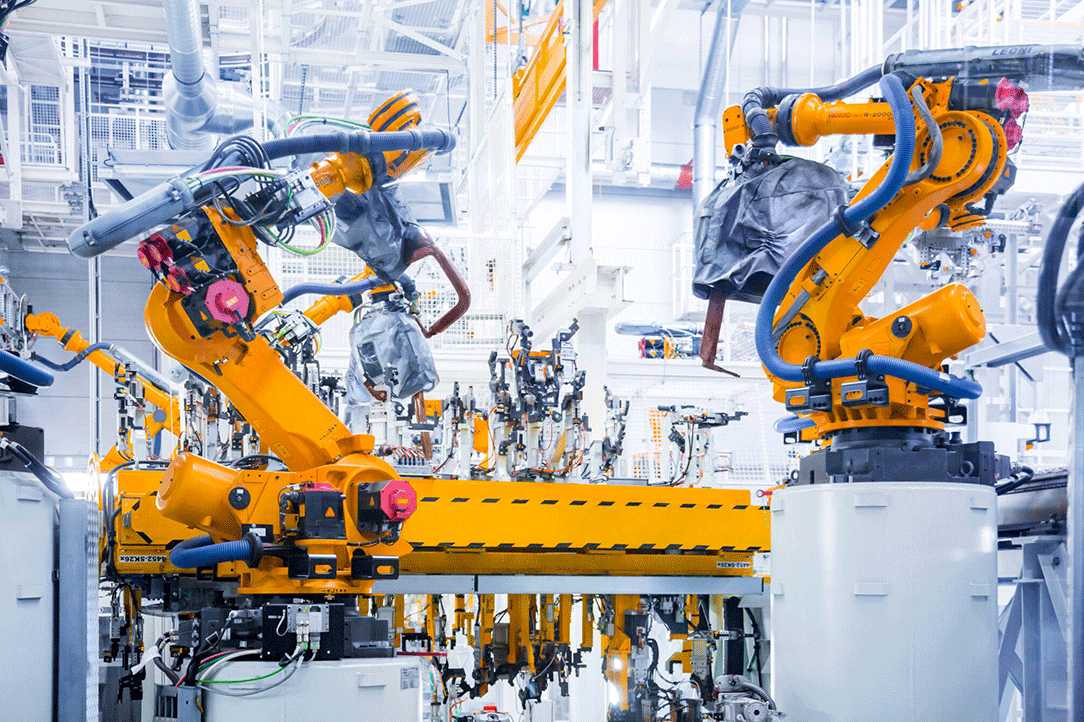

In recent years, the manufacturing sector has witnessed a transformative shift driven by the rise of advanced robotics. As technology continues to evolve, robotics are increasingly playing a pivotal role in enhancing production processes, boosting efficiency, and driving innovation. This blog explores the impact of advanced robotics on the future of industrial manufacturing and briefly touches on how LeisterTech is leveraging these technologies to enhance their product offerings.

1. Revolutionizing Manufacturing Processes

Advanced robotics have revolutionized manufacturing processes by introducing new levels of precision, speed, and flexibility. Robots are now capable of performing complex tasks with high accuracy, which has significantly improved production efficiency and product quality.

Key Impacts:

- Precision and Consistency: Modern robots are designed to execute tasks with exceptional precision, reducing the margin for error and ensuring consistent product quality. This level of accuracy is particularly valuable in industries such as electronics, automotive, and aerospace, where even minor deviations can lead to significant issues.

- Increased Speed: Robotics have accelerated production cycles by performing tasks at speeds that far exceed human capabilities. This speed boost allows manufacturers to meet higher demand and achieve faster turnaround times without compromising quality.

2. Enhancing Flexibility and Adaptability

The ability of advanced robotics to adapt to various tasks and production requirements has made them indispensable in the modern manufacturing landscape. Robots can be programmed and reconfigured to handle different processes, making them highly versatile and adaptable.

Key Impacts:

- Reconfigurable Systems: Advanced robotics can be easily reprogrammed to accommodate changes in production requirements or product designs. This flexibility enables manufacturers to quickly adjust to new market demands or shifts in production priorities.

- Scalability: Robotics systems can be scaled up or down based on production needs, providing manufacturers with the ability to efficiently manage varying production volumes and optimize resource allocation.

3. Improving Workplace Safety

The integration of robotics into manufacturing processes has significantly improved workplace safety by reducing the need for human intervention in hazardous or repetitive tasks. This shift has not only enhanced worker safety but also contributed to a more efficient and productive work environment.

Key Impacts:

- Hazardous Task Automation: Robots can perform dangerous tasks such as handling hazardous materials, operating heavy machinery, or working in extreme conditions. By taking on these high-risk activities, robotics help minimize the risk of workplace accidents and injuries.

- Reduced Repetitive Strain: Robotics can handle repetitive tasks that may cause physical strain or fatigue in human workers. This reduction in repetitive strain helps prevent injuries and promotes a healthier work environment.

4. Driving Innovation and Growth

The adoption of advanced robotics is driving innovation and growth within the manufacturing sector. As robotics technology continues to advance, manufacturers are exploring new applications and possibilities that were previously unattainable.

Key Impacts:

- New Product Development: Robotics enable the creation of complex and innovative products that push the boundaries of design and functionality. The ability to produce intricate components with high precision has opened up new opportunities for product innovation.

- Enhanced R&D Capabilities: The use of robotics in research and development has accelerated the pace of innovation by enabling rapid prototyping, testing, and iteration. This acceleration allows manufacturers to bring new products to market more quickly and stay ahead of industry trends.

5. LeisterTech’s Exploration of Robotics Technologies

At LeisterTech, we recognize the transformative potential of robotics in industrial manufacturing and are actively exploring how these technologies can enhance our product offerings. By integrating advanced robotics into our solutions, we aim to deliver even greater levels of efficiency, precision, and innovation to our clients.

How LeisterTech is Leveraging Robotics:

- Cutting-Edge Integration: LeisterTech is incorporating advanced robotics into our machinery and equipment to improve performance and operational capabilities. Our goal is to provide solutions that leverage the latest robotics technology to meet the evolving needs of our clients.

- Continuous Innovation: We are committed to staying at the forefront of robotics advancements, ensuring that our products incorporate the most recent innovations and deliver the highest levels of efficiency and reliability.

Conclusion

The impact of advanced robotics on the future of industrial manufacturing is profound and far-reaching. By revolutionizing processes, enhancing flexibility, improving safety, and driving innovation, robotics are reshaping the manufacturing landscape and creating new opportunities for growth.

As LeisterTech continues to explore and integrate robotics technologies into our product offerings, we remain dedicated to delivering solutions that harness the power of advanced robotics to drive efficiency, precision, and innovation. Embracing these technological advancements ensures that we stay at the cutting edge of the industry and continue to provide our clients with the highest quality machinery and equipment.